Japan is well-known across the world for its uncompromising standards. When it comes to aesthetics, durability and craftsmanship, the country spares no efforts to ensure the best results. Naturally, to satisfy the expectations of Japanese retailers and private level sellers, an OEM leather goods manufacturer India for Japan must follow rigorous quality control processes at every stage of production.

Right from the stage of sourcing raw materials to final shipment, the best Indian exporters ensure strict quality control at every stage. Find out how they take care of this.

Careful selection of raw materials

Top-notch exporters in India try to obtain the most superior raw materials, to ensure quality leather goods production. They work closely with certified tanneries, for sourcing top-grain and full-grain hides that satisfy the quality benchmarks of Japanese businesses.

They inspect each hide carefully, to check:

- Thickness,

- Texture and

- Natural imperfections

Only those materials that pass strict grading criteria move forward to the production stage. This ensures consistency across batches.

Advanced tanning and eco-friendly processing

Indian manufacturers are investing in advanced tanning methods, to cater to the growing sustainability priorities of Japanese businesses. These include:

- Chrome-free processes,

- Vegetable tanning, and

- Water-efficient processes

Furthermore, as a reliable Vegan leather supplier from India to Japan, exporters now offer superior plant-based and recycled leather alternatives. In addition to providing these eco-friendly options, manufacturers ensure that such materials undergo the exact same colorfastness, flexibility, and durability tests as authentic leather. Consequently, these products meet high-performance standards while satisfying the growing demand for sustainable fashion. This ensures eco-conscious products with no compromise on the performance front.

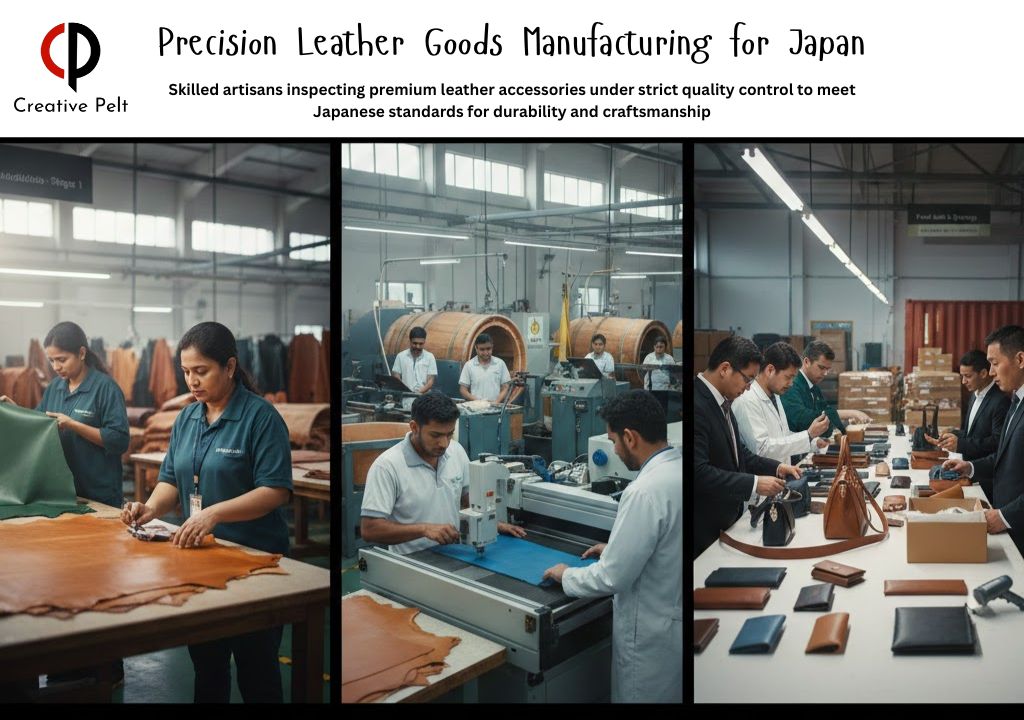

Precision manufacturing with skilled craftsmanship

A perfect combination of advanced equipment and skilled artisans defines the ability of a premium leather goods exporter from India to Japan. Through standardized operating procedures, such exporters are able to maintain precision cutting, reinforced stitching and uniform finishing.

Quality supervisors monitor each stage of production. They ensure that all leather accessories – bags, wallets or belts – satisfy exact size, strength, and finish specifications demanded by Japanese bulk buyers.

Multi-level quality inspection systems

Indian exporters now use multi-level inspection protocols for strict quality control. During the initial stage of assessment, material defects are focused on. During mid-production inspections, accuracy of construction is evaluated.

In the final inspection stage, appearance, packaging and durability are properly assessed. Products are tested for tensile strength, abrasion resistance and color bleeding to make sure that they will last and be usable in diverse conditions.

Secure packaging and compliance-ready shipping

Finished goods are carefully packed before being exported. Moisture-resistant, damage-proof materials are used for packing them. Exporters label, barcode and carry out documentation as per Japanese import regulations.

They also carry out a proper final audit of each shipment, to ensure compliance and order accuracy. With such attention to logistics, they can ensure proper product quality throughout transit. Customers can be more assured about the reliability of their ordered products.

Quality control is not just a single step for any reputed Indian leather manufacturer for Japan. The best manufacturers and exporters use multiple steps to satisfy and surpass the expectations of Japanese retailers and private label businesses. This has made India a reliable partner for sustainable and premium leather goods in the Japanese market.